The Cartridge Case

The cartridge case is the very heart of reloading. It is the one completely reusable component that makes the practice of “reloading” feasible. The concept of metal-cased, or “fixed” ammunition is actually a relatively recent development. First produced in viable forms in the early 1850s, today’s modern cartridge has its roots in the .22 Short Rimfire. The idea of a “cartridge,” however, is by no means new. The use of pre-measured charges of gun powder and bullet rolled into paper cartridges is believed to date back to the early 1600s, when King Gustavus Aldophus of Sweden ordered his soldiers to carry their ammunition in this manner. In fact, the word “cartridge,” is derived from the Latin word for paper, charta. The goal of carrying “fixed” ammunition was to provide more consistent charges than might otherwise be obtained by dumping the powder from a horn or flask, to reduce the spillage associated with using a powder measure in the field, and most importantly to expedite the soldier’s rate of fire. In use, the cartridge was torn open, and the powder contained in it was dumped down the barrel. The ball/bullet was then rammed down on top of the powder, with the cartridge paper sometimes being used as a wadding between powder and bullet. In the two-hundred plus years that this system of loading was widely used, various materials were used in lieu of paper, including linen and silk. Over the years these paper cartridges progressed to combustible cartridges, which were widely used in the American Civil War. Made from nitrated paper or linen, the combustible cartridges were loaded (from either the muzzle or breech, depending on the gun’s design) into the firearm whole, and completely consumed upon firing. Combustible cartridges were made for a wide variety of weapons at this time, particularly revolvers. The best known are probably the linen cartridges used in the Sharps rifles and carbines.

Combustible cartridges solved many of the problems associated with carrying loose powder, but they were still fragile, and had to be handled with care. They were susceptible to moisture, and could be easily damaged during the loading process. The combustible cartridge was a major step forward, but was clearly not the final answer. As various types of case materials were tried, metallic cartridges came into being. Some of the original metallic cases were formed from extremely thin materials, such as foil. Although the foil solved many of the problems associated with moisture, they were still fairly fragile. As the mechanisms for repeating firearms developed, stronger cases that were able to withstand cycling and loading through the action evolved.

There were a number of fascinating case designs developed during the years between 1840 and 1865, with varying degrees of success. Systems developed during this period included the Pinfire, Teat Fire, Morse, Inside Pinfire and a host of others. Most were fragile, complicated and not readily adaptable to the advances in firearms design that were also taking place. There was even some experimentation with the caseless concept, such as the caseless “Volcanic” cartridge. The Volcanic used what amounted to a Minie ball that had its hollow base filled with powder, and sealed with a self contained primer.

The most significant development during this period, however, was the rimfire cartridge. Utilizing a self-contained priming system, rimfires became tremendously popular in a wide variety of calibers. Ranging from the Flobert BB cap (essentially a lead BB seated in a percussion cap), to large military cartridges like the .44 Henry Flat and the .56-56 Spencer, rimfire cartridges served a wide variety of roles. Although the rimfire system was a quantum leap forward, it still had some drawbacks. The manufacture of rimfire cases, even in the larger calibers, was relatively inexpensive. However, once fired, they could not be conveniently reloaded. In order to ensure reliable ignition, the case rim must be thin enough to allow the priming compound to be crushed by the hammer’s blow. This in turn limits the pressures that can be used with this type of ignition system. While this posed no problem when black powder was the primary small arms propellant, this weakness doomed the rimfire system for more powerful applications when smokeless propellants came on the scene. The use of rimfires today is essentially limited to the familiar .22 caliber rimfire family of cartridges, which operate at relatively low chamber pressures.

As propellants, bullet design, and firearms have evolved, cartridge design has evolved right along with them. Today, there are three (3) general shapes of cartridges, which may be further defined by head type. The three basic case shapes are: bottle-necked designs such as the .30-06 and the 7mm Remington Magnum, straight-walled cases such as the .38 Special and the .45-70 Government, and the least common, the tapered cases such as the 9mm Luger and the .30 Carbine. Individual cartridges may then be further described by their case head design, which will fall into one of the following categories; rimmed, semi-rimmed, rimless, belted, and rebated. Each design was produced for a specific reason, which may or may not still be applicable today.

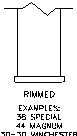

Rimmed

Rimmed cartridges represent the oldest case head design still in widespread use. As the name implies, a rimmed case is distinguished by a rim that extends outward from the head of the case, to a diameter noticeably larger than the case body. Today, the rimmed case is most commonly associated with cartridges designed for use in revolvers. The purpose of the rim (in any type of firearm) is to provide for positive headspacing. In many of the earliest cartridge designs, case shoulders were very long and sloping, making them difficult to reliably headspace on the shoulder.

from the head of the case, to a diameter noticeably larger than the case body. Today, the rimmed case is most commonly associated with cartridges designed for use in revolvers. The purpose of the rim (in any type of firearm) is to provide for positive headspacing. In many of the earliest cartridge designs, case shoulders were very long and sloping, making them difficult to reliably headspace on the shoulder.

Some examples are the .22 Hornet, the .303 British, and the .32-20 WCF. It should also be remembered that mass production techniques of this era were not as precise as they are today, and larger tolerances were commonly encountered. Therim proved to be a remarkably simple solution to the problem of creating a positive step upon which a cartridge could be headspaced, and yet was easily manufactured. Rimmed cartridges have certain drawbacks, but these were of no concern at the time the design was introduced. The biggest of these is the difficulty in obtaining reliable feeding from a box type magazine. The rims tend to interfere with each other during the feeding cycle. This occurs when the rim of the cartridge being chambered tries to strip the round beneath it, since the rims do not easily ride over one another. In box magazine fed rifles, such as the .303 British Enfield, this is overcome only by careful arrangement of the cartridges when the magazine is initially loaded. Failure to do so will result in jams and misfeeds. This is of no concern in single-shots, revolvers, tubular magazines, and double-rifles, and the rimmed case continues to serve quite well in all of these applications.

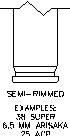

Semi-Rimmed

As box magazines became more prevalent for military use, some solution to the feeding problems of rimmed cartridges had to be found. The semi-rimmed case design represents one of the first steps taken to solve this problem. The basis of the semi-rimmed design is a rim only slightly larger than the case body itself. Most of the bottle-necked cases that were originally designed as semi-rimmed had more pronounced shoulders than most of the earlier rimmed cartridges. Within a few short years, production techniques had become consistent enough that cartridges could be reliably headspaced off the shoulder alone, causing little further need for this cartridge type. The Japanese 6.5x50mm Arisaka is a typical example of a semi-rimmed service cartridge. It is worth noting that the next Japanese service cartridge, the 7.7mm Arisaka, was a true rimless design.

be reliably headspaced off the shoulder alone, causing little further need for this cartridge type. The Japanese 6.5x50mm Arisaka is a typical example of a semi-rimmed service cartridge. It is worth noting that the next Japanese service cartridge, the 7.7mm Arisaka, was a true rimless design.

Not all semi-rimmed cases were of bottle-necked design. The semi-rimmed case was also used in many of the early straight-wall automatic pistol cartridges designed by John M. Browning. The most popular of these still in use today are the .25 ACP and the .38 Super.

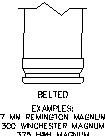

Belted

The belted case might be thought of as an alternative to the semi-rimmed design,  as it was intended to accomplish the same goals. The design is an English innovation, credited to the gunmaking firm of Westly Richards. Intended to combine the positive headspacing of a rimmed case, the belted case gives smooth, reliable feeding from a box magazine. The defining characteristic of these cartridges is a small band, or belt, around the head of the case, just ahead of the extractor groove. In use, the belt acts in exactly the same manner as a rim. Originally, this was an absolute necessity, owing to the steeply sloping shoulders of many of the first belted cases.

as it was intended to accomplish the same goals. The design is an English innovation, credited to the gunmaking firm of Westly Richards. Intended to combine the positive headspacing of a rimmed case, the belted case gives smooth, reliable feeding from a box magazine. The defining characteristic of these cartridges is a small band, or belt, around the head of the case, just ahead of the extractor groove. In use, the belt acts in exactly the same manner as a rim. Originally, this was an absolute necessity, owing to the steeply sloping shoulders of many of the first belted cases.

At the time of the belted case’s introduction, England was still making the transition from black powder to smokeless propellants, in the form of Cordite. Cordite is a long strand double-based propellant, with the length of the individual kernels equaling the length of the combustion chamber. In production, small “bundles” of Cordite were inserted into a straight-walled case, which was then necked down to its final shape, and the bullet seated. As a result of this manufacturing method, most cartridges designed for use with Cordite have very long, sloping shoulders. Again, this proved to be no problem, as a large percentage of these cartridges were being chambered in single-shots or double rifles, and were of rimmed (or as the British call them, “flanged”) design. At approximately the same time, the bolt-action was rising in popularity, forcing gunmakers to develop a case that would feed reliably from a magazine. This was the origin of the belted case design. Since then, it has been a traditional British practice to offer both rimmed and belted designs of the same cartridge, for use in either double rifles or bolt actions, as appropriate.

The first two belted cartridges to gain notoriety here in the U.S. (although developed decades earlier in England) were the .300 and .375 H&H Magnums introduced to American shooters in the early thirties. Since then, the belted case has served as the basis for a great many “Magnum” cartridges. In all honesty, the vast majority of these modern magnums have shoulders that are perfectly adequate for headspacing, leaving the belt to serve no truly functional purpose. Some examples of the belted case design are the old .300 H&H, and the newer .300 Winchester and 7mm Remington Magnums. There have been very few examples of belted pistol cases, other than wildcats such as the .40 G&A.

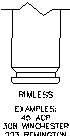

Rimless

The most commonly used head design today is that of the rimless case. Despite the “rimless” designation, the case does indeed have a rim to facilitate extraction. In this design, however, the rim does not extend beyond the case body. Rather, the rim diameter is approximately equal to the diameter of the case body itself just ahead  of the extractor groove. Designed for flawless feeding through the various weapon types that were emerging in the late 1890s, the rimless case has become the most popular and widely used head type in the world. With no protruding rims or belts to complicate feeding, the rimless case has proven itself eminently well suited to later military developments, such as clip loading, magazine and belt-fed weapons. The first successful rimless design adopted by the U.S. was the .30-03 Springfield (redesigned as the .30-06 some three years later), although the U.S. military had been looking at rimless designs for at least a decade prior. Rimless service cartridges have been the standard ever since, progressing from the .30-06 to the 7.62mm NATO/.308 Winchester to the current 5.56mm NATO/.223 Remington.

of the extractor groove. Designed for flawless feeding through the various weapon types that were emerging in the late 1890s, the rimless case has become the most popular and widely used head type in the world. With no protruding rims or belts to complicate feeding, the rimless case has proven itself eminently well suited to later military developments, such as clip loading, magazine and belt-fed weapons. The first successful rimless design adopted by the U.S. was the .30-03 Springfield (redesigned as the .30-06 some three years later), although the U.S. military had been looking at rimless designs for at least a decade prior. Rimless service cartridges have been the standard ever since, progressing from the .30-06 to the 7.62mm NATO/.308 Winchester to the current 5.56mm NATO/.223 Remington.

Rimless cartridges may be found in either straight-wall or bottle-necked configurations. Headspace in the bottle-neck designs is based upon the datum line, or midpoint of the shoulder. To the handloader, this means that sizing die adjustment is critical to assure proper and safe functioning of reloaded rimless cartridges. If the shoulder is pushed back by a die that is adjusted down too far, excessive headspace will result. This causes poor ignition, accuracy problems, short case life, and poses a serious safety hazard. Despite these potential problems, the rimless design is still one of the best combinations for reliable headspacing, trouble-free feeding, and adaptability to a wide variety of action types.

In straight-wall cases, the rimless design has become the standard for semi-automatic pistols, from the time-honored .45 ACP, right up to the most modern designs such as the .40 Smith & Wesson. The straight-wall (and/or tapered) rimless design has also been used for some rifle cartridges, such as the .30 Carbine. In either rifle or pistol, positioning (headspacing) of a straight-wall rimless case is controlled by the case mouth, stopping on a corresponding ledge on the inside of the chamber. As such, case length is a determining factor in controlling headspace. Positive headspacing can also be influenced by the type and degree of crimp. For example, a .45 ACP case of proper length may headspace reliably if given a slight taper crimp, yet demonstrate excessive headspace if a heavy roll crimp were applied. As a rule, cases which headspace on the case mouth should only be taper crimped, and only slightly at that. At present, it appears that the rimless case, in either straight-wall or bottle-necked configurations, will continue to be the most common design for the foreseeable future.

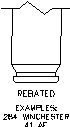

Rebated

Currently undergoing a revival in the WSM and ultra mags, the rebated case is characterized by a rim that is noticeably smaller in diameter than the case body. The intent of this design is normally to offer increased case capacity without altering or enlarging an existing bolt face. The .41 AE is perhaps the best example of the rationale behind this particular head design.

Developed by Evan Whilden, then with Action Arms, the .41 AE utilizes the same case head dimensions as the popular 9mm Luger. By increasing the case body dimensions enough to accept a .410” diameter bullet, Whilden gave a substantial boost in performance to 9mm handguns. By keeping the same head dimensions, converting a standard 9mm to accept the more powerful .41 AE was simply a matter of switching barrels, magazines and recoil springs. No costly modifications to the slide or extractor were required. In the .284 Winchester, the larger body diameter allowed .280 Remington performance from a short action, again without modification to the existing bolt face. While the rebated design is an excellent concept, it has met with little commercial success.

enough to accept a .410” diameter bullet, Whilden gave a substantial boost in performance to 9mm handguns. By keeping the same head dimensions, converting a standard 9mm to accept the more powerful .41 AE was simply a matter of switching barrels, magazines and recoil springs. No costly modifications to the slide or extractor were required. In the .284 Winchester, the larger body diameter allowed .280 Remington performance from a short action, again without modification to the existing bolt face. While the rebated design is an excellent concept, it has met with little commercial success.